What We Do

Team Jatayu Racing BAJA is an engineering project team which annually designs, builds, tests and races an off-road vehicle to compete in competitions like, Baja Student India, Baja SAE India, Enduro Student India, Mega ATV Championship, FMAE Baja and Baja SAE USA. We dedicate ourselves in making our ATV strong enough to cross all the hurdles. Every year, we try to make our ATV lighter, faster and more durable.

Building an ATV mainly involves three fundamental phases. We pin-point the errors in our previous creation and try to quarantine them before the actual visualization of our car. The first phase is the DESIGNING of the ATV virtually. The chassis and the sub-assemblies are modelled using CAD softwares and tested virtually through analysis softwares. The next phase involves the FABRICATION of our ATV. We employ a multitude of value added processes like cutting, grinding, drilling, brazing and welding to manufacture the components designed by us, adding life to our vehicle. From the chassis, transmission, gearbox to the braking and even the data acquisition system, the work is done in our college workshops or at some machining centers with our own hands. The next and the most important phase is ASSEMBLING and TESTING. Endurance is judged through the various tests under extreme conditions, we try to make it immune to failures and breakdowns.

We don’t just bring our car to the competition, but also the meticulous effort, the goodwill of our sponsors, seniors and the name of our college. This makes our car nearly unbreakable.

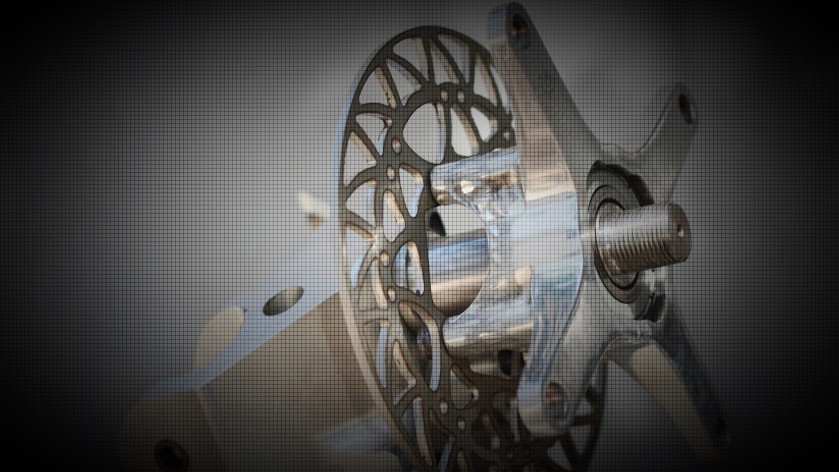

Braking

The braking department is responsible for making all the four wheels lock at anytime. The braking assembly is designed, built or tweaked by us.

Design

The design department usesvarious CAD softwares to design the ATV. The design team ensures that the vehicle is light weight, durable and uses minimum material. After the designing part is done, the analysis or virtual testing of the vehicle is done.

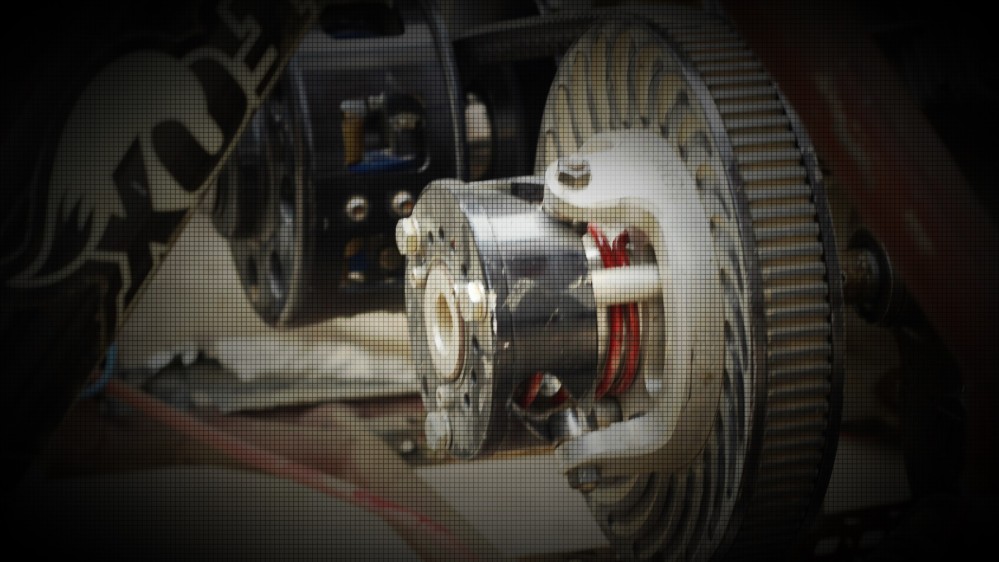

Powertrain

The power train department handles components that generate power and deliver it to the vehicle. Power train includes the engine, transmission, gearbox, drive shafts and final drive.

Suspension and Steering

The suspension department handles the system of tires, shockers, steering and the linkages that connects the wheels and the vehicle. The vehicle's handling and dynamics mostly depend on the suspension geometries..

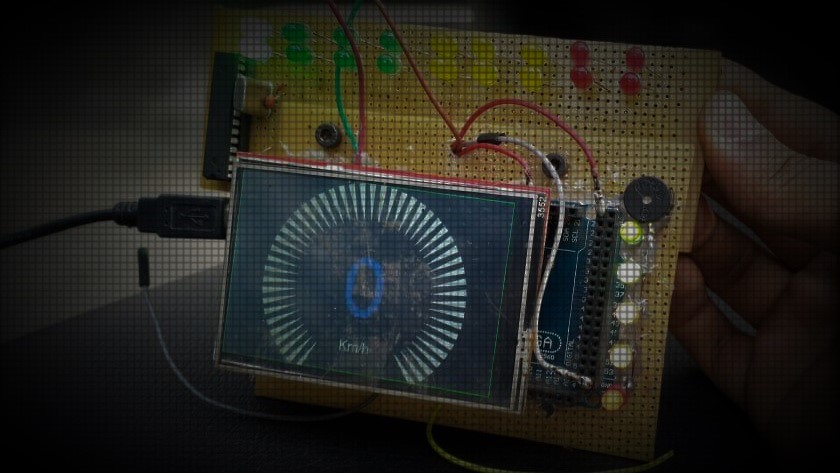

Data Acquisition

The DAQ department is responsible for all the electrical and electronic systems on the ATV. It procures the data and and displays it in an easy manner.

Sales

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Sapiente esse necessitatibus neque.